Manufacturing

Chemical Listing

Chemical Listing

Chemical Listing

Chemical Listing

We are Europe’s largest provider of specialist drying services to the chemical industry. With over 30 years of experience in spray drying and other drying techniques, we offer customers many options to their drying problems. These include spray drying, spray cooling, vacuum drying, calcining, liquid blending and powder blending.

We work with clients’ R&D teams across Europe and help them to advance their product development. Our flexible set up and approach means we are able to respond to our customers' needs by providing tailored solutions. We are able support both fast turnaround projects as well as longer-term development processes with our ability to take product development from the initial laboratory testing through a pilot plant phase and into commercial scale production.

Established in 1937, we have an extensive range of speciality tri-valent chromium compounds which we supply to industries worldwide. These are available in both liquid and powder form to suit a wide range of applications including catalyst manufacture, dye manufacture, oil drilling fluids, adhesive preparations, metal treatment and plating.

We also have wide range of speciality metal salts including sodium, potassium and calcium-based products. These are typically used in a wide range of industries such as food, animal feed production, pharmaceutical and general chemicals.

With almost 80 years of experience, we also manufacture a range of de-icers, acetates, formates, propionates, lactates and chrome chemicals.

Plater Group have a small team

of highly experienced craftsmen.

This enables us to carry out all planned preventative maintenance, repairs and small project

work on site.

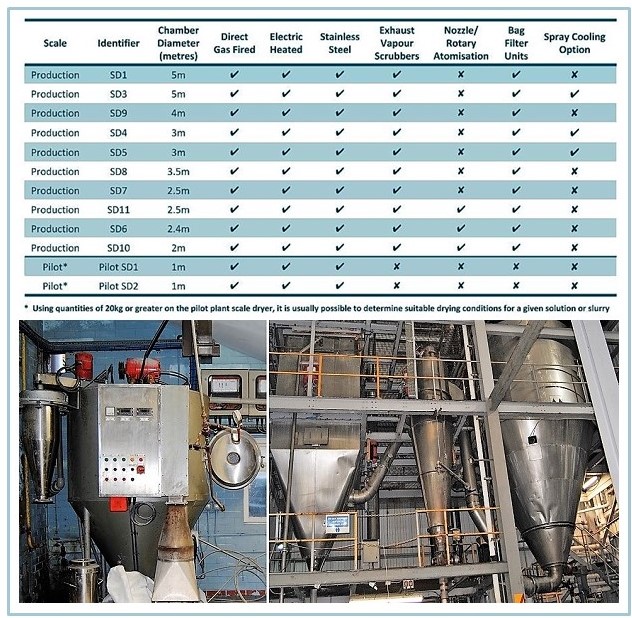

Plater Group has 10 commercial

scale spray dryers and 2 pilot scale spray dryers.

We offer a complete service from the lab bench to full scale production.

Glossop is home to the Plater

Group accounts department, production services,

quality and health & safety teams.

Plater Group has 2 commercial

scale spray coolers and 2 pilot scale spray coolers.

We offer a complete service from the lab bench to full scale production.

Our 8 acre site in Glossop

employs over 38 people

in production, sales, administration and engineering.

Plater Group can offer the

facility to melt out products which are solid at room temperature.

We use steam fed melting stations prior to carrying out the spray cooling service.

Plater Group can load and

unload any vehicle on site,

including loading and unloading containers, both 20' and 40' FCL's.

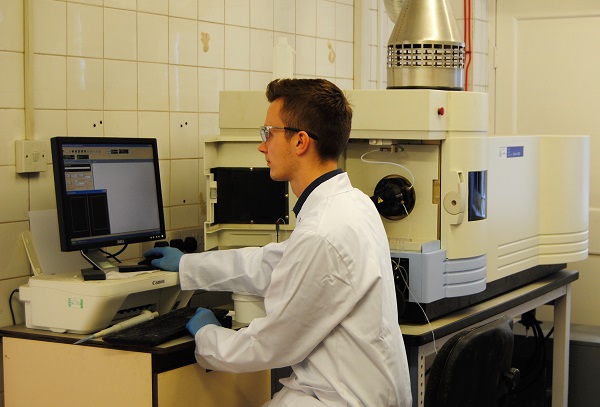

Plater Group has a fully

equipped QC laboratory, staffed by professional chemists, who can

carry out a full range of analytical tests as well as offering ICP and IR spectroscopy.

We also have a Malvern particle size analyser for our spray dried products.

Plater Group have a number of warehouses on site for the storage of raw materials, blends and customers’ finished products. IBCs, drums and packaging materials are also stored on site.

Our office entrance is between

house numbers 230 and 232 High Street West, Glossop, SK13 8ER.

Drive over the small bridge and press the entrance call button.

Commercial vehicle access is along Dinting Lane, Glossop SK13 7GA

Our on-site weighbridge is used

to monitor the weight of commercial vehicles and bulk tankers, ensuring they are weighed in

and out accurately, to guarantee vehicle safety guidelines are adhered to.

The facility is also a public weighbridge, allowing members of the public to weigh

caravans, motor homes etc. for a small fee.

Plater Bio manufactures a range

of novel biostimulants for the agriculture and horticulture industries.

All our products are manufactured exclusively on-site in Glossop.

Plater High Purity offers a

wide range of acids and alkalis packed in a range of pack sizes

from 1L to 1000L, utilising our clean room facility.

1000L IBC’s offer a versatile storage option for customers requiring more than drum quantities but unable to take bulk deliveries.

Plater Group provides a

Calcining facility on a toll basis and is one of the few companies in Europe to offer this

facility.

Calcining is the process of heating a powder to a temperature in excess of 500°C to remove

all residual moisture content, or to initiate a high temperature chemical reaction within

the solid.

Plater Group has a wide range

of blending vessels from 20L to 30,000L capacity to allow us to offer the complete service

to our customers.

Most vessels are fitted with agitation, heating and cooling facilities.